By their very nature, composite waste cannot easily find a suitable channel allowing the reuse of each of its components. In fact, neither chemical recycling nor mechanical recycling makes it possible to separate multi-component materials into reusable materials without any further step.

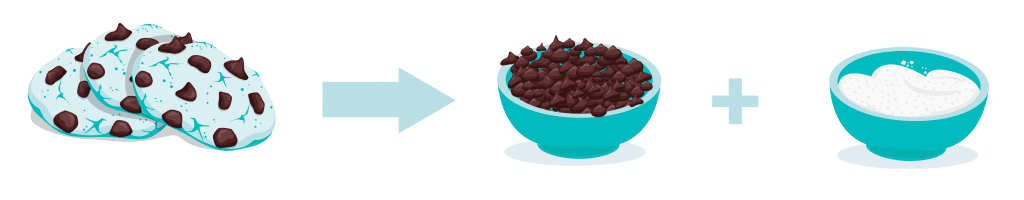

Mechanical recycling is not very effective, not to say completely ineffective on composite waste, and flexible. Indeed, a composite, even crushed, remains a composite and the purity of the residual material is generally not sufficient to reintegrate it as it is in an industrial process. Try to crush a cookie and you will never recover flour and chocolate chips.

Chemical recycling has the major advantage of not being very demanding on the quality of incoming waste. It becomes possible to recycle composite products not suitable for mechanical recycling, since it implements a heat treatment, intended to return to the basic substances constituting the materials. However, after processing, you will not recover a ready-to-use material. Although these recycling methods are more suitable for unsorted waste streams and composite products, the by-products remain of low added value and treatment costs can be high. Furthermore, PVC is not a great friend of chemical recycling due to its chlorinated composition which can generate post-treatment difficulties.

In order to meet the needs of manufacturers to recycle their PVC-based composite waste , the Polyloop project wishes to unlock these technological obstacles by using a proven physico-chemical recycling process, which has been tested for 20 years on an industrial scale, by integrating it in a smaller scale recycling unit.

This technology can be qualified as STRAP methodology (solvent-targeted recovery and precipitation). This process enables to obtain a regenerated material of high quality, since it does not use depolymerization of the polymer chains. The physico-chemical process is based on a selective dissolution of PVC, then its precipitation. It is leading to the production of a recycled polymer material in the form of compound, ready to use and of high purity.

This physico-chemical process enables to separate the PVC contained in a product from any other component such as fiber reinforcements, aluminum sheets, wood, another polymer…

We like to take the example of the cookie: with Polyloop you get your freeze-dried cookie powder (representing the formulated compound of PVC) and on the other hand chocolate chips (representing the insoluble ones). You can then reuse them to make another (recycled) cookie or a chocolate pie!

Our process allows you to integrate your recycled raw materials directly into your production site.

The unit is installed on an outdoor platform near your buildings. Your materials are therefore recycled and valued thanks to Polyloop.

To find out more about recycling your materials, go here.