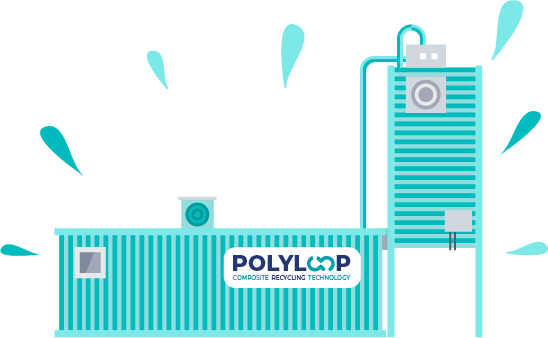

The change of scale, from the Seveso factory to that of a container, is not done in the twinkling of an eye! More than a kilometer of wiring, tangled but accessible piping, etc … The development of the recycling unit involves a complete reengineering of the processes while optimizing their operation.

There is a real “big” challenge when it comes to equipment that is easy to use on a daily basis.

The transition can be compared to that of computer to smartphone: a complex machine with intuitive use.

FROM HEAVY INDUSTRY TO SMART FACTORY : AN EQUIPMENT CLOSER TO YOUR WASTE

In order to meet your quality requirement for regenerated R-PVC, Polyloop has developed unique know-how allowing you to perfectly control the precipitation and drying conditions of your PVC compound: its particle size, its homogeneity, its flowability, etc… , these are all parameters mastered by the Polyloop process and customizable!

Recycling flexible PVC composites through a STRAP process is not an easy task. Some are made of fibers that can wrap around a stirrer during the dissolving step. This comes out from our past industrial experience. To overcome this sensitive situation, Polyloop has developed an innovative and patented loading and dissolution system. The waste is inserted through a modular according to the waste, like a washing machine drum. This allows:

Contact the polyloop team to design your own solution.

Recycling flexible PVC composites through a STRAP process is not an easy task. Some are made of fibers that can wrap around a stirrer during the dissolving step. This comes out from our past industrial experience. To overcome this sensitive situation, Polyloop has developed an innovative and patented loading and dissolution system. The waste is inserted through a modular according to the waste, like a washing machine drum. This allows:

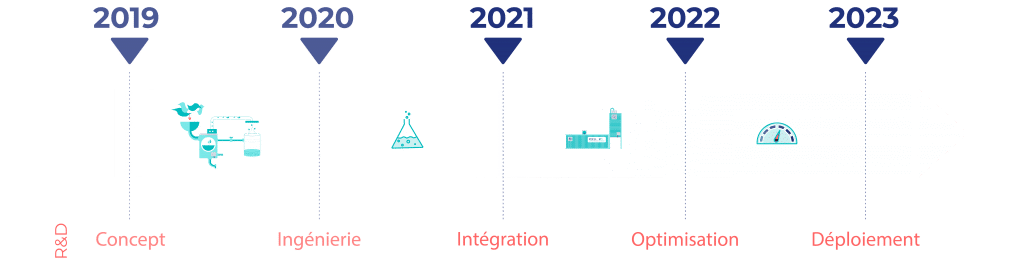

Since it was launched, Polyloop has benefited from the support of Ademe through a future investment plan (PIA 3 Ecocir) for a period of 3 years and a total amount of 2.7 million euros.

Since 2020, the centre of excellence AXELERA is supporting us in the development of the project, in particular by helping us to find financial leverage and to establish partnerships with players in our sector of activity: green chemistry.

In addition, Bpifrance and Pulsalys have recognised Polyloop’s innovative values by labelling it a “Deeptech ” startup twice in 2020 and 2021.