350 million tons of plastics are produced every year. Polyvinyl chloride (PVC): third most used plastic in the world after polyethylene (PE) and polypropylene (PP).

About 40 million tons of PVC are produced, among which 5.2 million tones are produced in Europe. Produced mainly from two raw materials: sea salt (57%) and oil derivatives (43%), because of its intrinsic qualities and characteristics (rigid or flexible, opaque or transparent, neutral or coloured, etc.), PVC is used in many sectors (construction, medical, automotive, outdoor, etc.) which at this stage cannot do without it, as its multiple properties and its cost still make it indispensable.

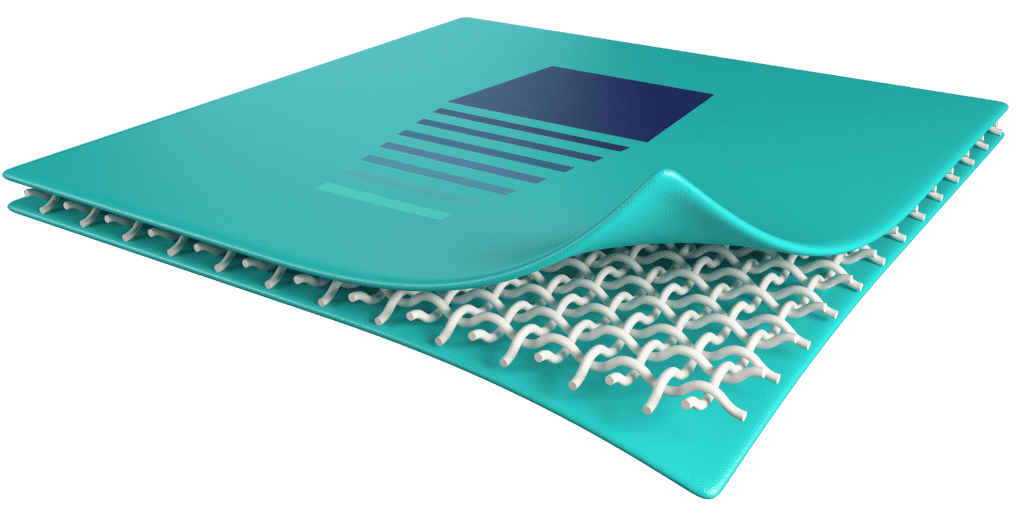

However, when the PVC matter is integrated into complex, multi-layered materials, it is qualified as rigid or flexible “composite PVC”.

Recycling flexible composite PVC waste, it’s possible!

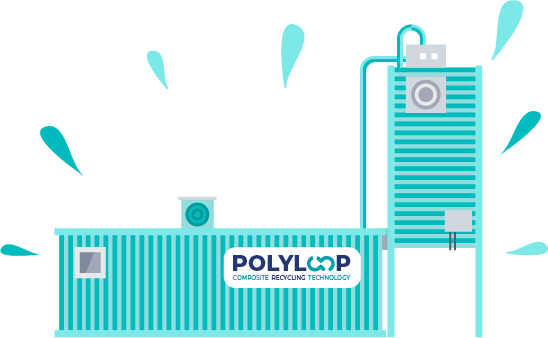

Polyloop® is on a niche market, that of PVC composites and wishes to avoid the landfill of the waste that is sent there today, due to the lack of effective solution for treating flexible PVC composites.

The industries using these materials surround us, covering floors, walls and roof! These materials dress us (sportswear, footwear), equip us (leather goods), shelter us. We walk on them, they allow us to enjoy the outdoors (garden pipes, outdoor furniture). They are everywhere and we are note even aware of their presence.

Polyloop may be a solution for you. Contact our team for more information.

Three steps before starting to recycle your waste!

Qualitative waste studies

Quantitative waste studies

(available Oct 2021)

The qualitative and quantitative studies are essential before ordering a Polyloop unit.

Check of the eligibility of your waste.

Scale 1 recycling of your materials: produce with your recycled materials

The first functional unit will be available in 2022.

Qualitative and quantitative studies are necessary steps before ordering a unit.

Make a difference! Recycling is good, integrating recycled materials into your production is better!

Imagine a partial independence of your purchases: you do not buy your materials back which are contained in your production waste.

The Polyloop recycling technology allows you to recycle your waste directly on your industrial site: a compact and integrable recycling unit.

It allows you to recover your recycled raw materials ready for use thanks to its physico-chemical process: a recycling unit with high added value.

At Polyloop we talk about recycled raw materials because our process regenerates your materials.

You are able to produce and market a new range of products incorporating your recycled raw material, at proportions that are impossible today, while maintaining your quality requirements.

Do you want to know the impact of a Polyloop recycling unit in your production? Test the process with our profitability simulator: